This Polariscope adopts automatic Senarmont method to measure the internal stress in transparent objects . In the previous manual Senarmont method, the observer needs to determine the relatively brighter part and relatively darker part by their eyes, thus operation errors can not be prevented .

This device automatically detects the image luminance, thereby finding the relatively darker part precisely . By inputting sample photoelastic constant and thickness in advance , the stress value will be calculated by the computer . In addition, Sensitive Color method is used to clearly define the direction of stress.

Objects of Polariscope

float glass plate, automotive glass

crystal , quartz , lens glass

glass container , glass vial , water glass

glass wafer , glass tube , laboratory glassware

resin plate , resin film , mold injection resin products

industrial new material glass , optical new material glass

Measuring principle

The internal stress of glass and plastic products has a birefringent characteristic. In other words, if there is stress inside of these types of products, light from he polarized lamp will be divided into different units, which produces optical interference phenomenon (ripple patterns) in turn.

Application

Glass Inspection

Plastic Inspection

Crystal Inspection

Optical Fiber Inspection

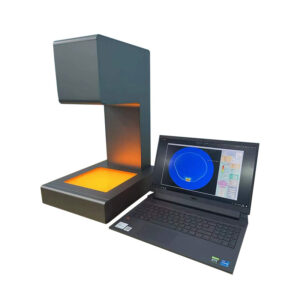

Detecting method : Sensitive Color + Senarmont

Retardation of full-wave plate : 560nm

Viewing field : 200mm*200mm

Optical retardation range : 0-280nm

Measuring height ( adjustable ) : max 240mm

Overall size : W280*D380*680mm

Voltage: 24VDC( with a AC/DC adaptor )

Light source : White fluorescent lamp

Weight : 15kg

Test Methods:

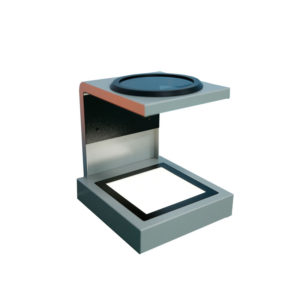

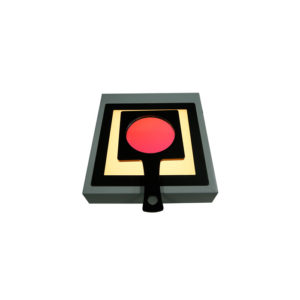

1.Sensitive Color Method

The background color is aubergine.

After putting a sample on the sample plate, the parts with green ,blue, orange and yellow stripes show the presence of stain. Whether it is compressive strain or tensile strain can be determined easily.

The part without strain has the same color as the background.

2.Senarmont Method

The viewing field is dark-brown .

After putting a sample on the Sample plate, pay attention to the part that is relatively darker in the viewing field . This part has the relatively larger strain . Then rotate the dial until the relatively brighter part can’t get darker.

Greatly improve the measurement accuracy with automatic Senarmont method

Real time display of stress presence

Equipped with a zoom lens for detection of small samples ;

Save data and images automatically with a laptop

Easy to operate , long serving life

Functions

Observe stress presence and stress distribution state

Measure glass temper grade

Measure optical retardation caused by residual stress