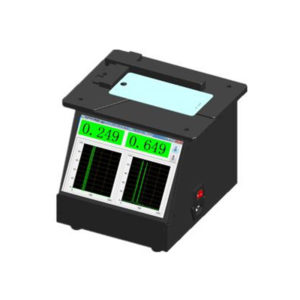

This AOI machine is designed for detecting defects online. It can automatically perform multiple functions such as sapphire lens defect detection, dimensional measurement, automatic loading and unloading.

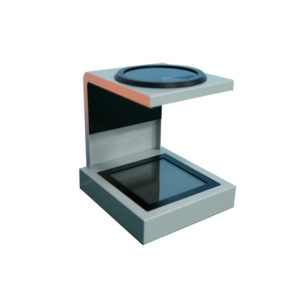

Measuring objects

Sapphire lens , cellphone lens , small-sized flat glass , metal or plastic parts

Functions

- Defects inspection

- Dimension measurement

- Automatic loading and unloading

Application

Other inspections

( optical processing, metal processing and manufacturing, electronic component manufacturing and other fields )