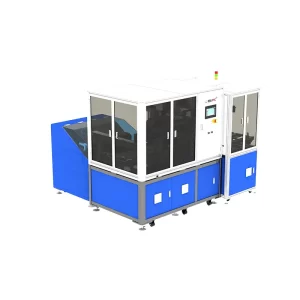

This device is mostly used to detect various defects on the PCB inner layer and outer layer board , such as short/open circuit, line width/ line distance tolerance, bump/ recess , pinhole, residual copper , scratch, hole plugs, hole, size and position errors, etc.

Measuring objects

Ordinary FR4 , high-frequency white board ,Teflon board , ceramic board and other hard board materials

Application

PCB Inspection