In modern manufacturing, ensuring the highest quality and reliability of products is essential. Scanning Acoustic Tomography (SAT) has become a critical tool in achieving this goal. This non-destructive testing (NDT) technology offers high-precision, real-time imaging of material defects that might otherwise remain undetected. With its ability to detect hidden flaws in a wide range of materials, SAT has revolutionized industries that rely on stringent quality control, such as semiconductor manufacturing, aerospace, automotive, and electronics.

In this blog post, we will dive into the core concept of scanning acoustic tomography, explore how it works, compare it to other testing methods, discuss its applications across industries, and examine the future of this game-changing technology.

Scanning Acoustic Tomography (SAT) is a sophisticated non-destructive testing technique that uses high-frequency sound waves to capture detailed internal images of materials. Unlike visual inspection, which only examines the surface of an object, SAT allows for an in-depth analysis of the material’s internal structure.

When the acoustic waves are directed through a material, they interact with the internal components, such as the interfaces between different layers, voids, cracks, and other structural features. These waves are reflected back to a series of sensors, which process the signals and create an image or map of the internal structure. This process is similar to how ultrasound is used in medical diagnostics, but with far higher precision and resolution for industrial materials.

The key components involved in SAT are:

Acoustic Waves: High-frequency sound waves are used to penetrate materials and reflect off internal defects.

Probes and Sensors: These are used to capture the reflected waves and convert them into usable data.

Data Analysis Software: Specialized software processes the data, creating a detailed, real-time image of the material’s internal structure.

Non-Destructive: SAT is a non-invasive technique that does not alter or damage the material being tested. This is crucial when testing expensive or delicate materials, where destructive testing would be impractical.

High Precision and Resolution: SAT offers extremely high precision, capable of detecting defects as small as a fraction of a millimeter. This level of detail is essential for industries where the smallest defect can result in failure.

Real-Time Imaging: SAT provides real-time feedback, allowing operators to immediately identify potential defects and make decisions quickly. This speeds up the manufacturing process and reduces downtime.

Parallel Probe Scanning: Multiple probes can be used to scan large areas simultaneously, increasing scanning efficiency and reducing inspection times.

The process of scanning acoustic tomography involves several stages that ensure accurate detection of internal material defects. Here’s a step-by-step breakdown of how SAT functions:

Emission of Acoustic Waves: High-frequency sound waves are emitted through a transducer (probe) onto the surface of the material. These waves travel through the material and interact with the internal structures.

Reflection of Sound Waves: As the waves encounter different material layers or defects (such as voids or cracks), some of the sound energy is reflected back towards the sensor, while the rest continues through the material.

Data Collection: The sensors placed around the material collect the reflected sound waves. These sensors are highly sensitive and can detect even the slightest variations in the reflected sound.

Image Construction: The reflected data is sent to a computer where it is processed into an image. The intensity and time delay of the reflected waves are used to construct a visual representation of the material’s internal structure.

Analysis: The resulting image is analyzed using specialized software that identifies potential defects such as delaminations, voids, cracks, and other structural issues.

Scanning Acoustic Tomography offers several advantages over other traditional non-destructive testing methods, such as X-ray. The table below summarizes how SAT compares to these methods in terms of precision, speed, and application.

Testing Method | Precision | Speed | Non-Destructive | Best For |

Scanning Acoustic Tomography (SAT) | Very High | Fast | Yes | Small-scale defects, composites, multilayer materials |

X-ray Inspection | Moderate | Moderate | Yes | Density and thickness variations |

Visual Inspection | High | Instantaneous | Yes | Surface defects |

As shown, SAT excels in precision, particularly in detecting micro-scale defects that other methods might miss. Its ability to scan large areas quickly and provide real-time feedback makes it an ideal choice for high-volume production environments.

Scanning Acoustic Tomography is used in several industries where high product quality and defect-free materials are critical. Below are some of the key industries that rely on SAT for quality control and defect detection:

Semiconductor Industry: SAT is particularly useful in inspecting the packaging of semiconductor devices, where defects like delaminations, voids, and cracks can compromise performance. SAT helps detect these defects without the need for destructive testing, ensuring the reliability of sensitive electronic components.

Aerospace Industry: In aerospace, where safety is paramount, SAT is employed to inspect critical parts such as turbine blades, engine components, and composite materials. It helps detect hidden internal flaws that could compromise the safety and performance of aircraft.

Electronics Industry: SAT is essential for inspecting printed circuit boards (PCBs) and other electronic components, ensuring that defects like micro-cracks or voids do not impact the functionality of the device.

SAT is capable of detecting a wide variety of internal defects that are often invisible to the naked eye. Some of the most common defects identified by SAT include:

Delaminations: Separation between layers in composite materials or multilayered products.

Voids: Empty spaces or air pockets within materials that can lead to material failure.

Cracks: Small fractures in materials that can compromise structural integrity.

Inclusions: Foreign materials or impurities trapped within a material that can affect its performance.

The ability to detect these defects early in the manufacturing process prevents costly product failures, product recalls, and safety incidents.

The technology behind Scanning Acoustic Tomography is constantly evolving. With advancements in artificial intelligence (AI) and machine learning, the capabilities of SAT are expanding. These technologies can be integrated into SAT systems to:

Automate defect detection: AI can be used to automatically analyze SAT images and identify defects without human intervention.

Enhance imaging capabilities: Machine learning algorithms can improve the resolution of SAT images, making it possible to detect even smaller defects.

Integrate with Industry 4.0: SAT can be integrated into smart manufacturing systems, where it communicates with other equipment and sensors to optimize production workflows.

As SAT technology continues to advance, it will become even more accurate, faster, and easier to integrate into manufacturing processes.

In today’s fast-paced, high-demand manufacturing environment, Scanning Acoustic Tomography is crucial for maintaining high-quality standards and meeting the rigorous demands of various industries. SAT helps manufacturers:

Ensure product integrity: By detecting defects early, SAT ensures that only high-quality products are delivered to customers.

Reduce production downtime: With faster scanning and real-time analysis, SAT minimizes the need for extensive rework or production delays.

Maintain regulatory compliance: SAT helps manufacturers meet stringent industry standards and regulations, particularly in safety-critical sectors like aerospace and automotive.

Scanning Acoustic Tomography (SAT) has become an essential tool in modern manufacturing, offering non-destructive testing with high precision and the ability to detect internal defects. It is transforming industries by enhancing product quality, increasing operational efficiency, and lowering costs related to defective materials. In sectors like semiconductor manufacturing, aerospace, automotive, and electronics, SAT enables companies to uphold stringent quality standards and stay competitive in the global market.

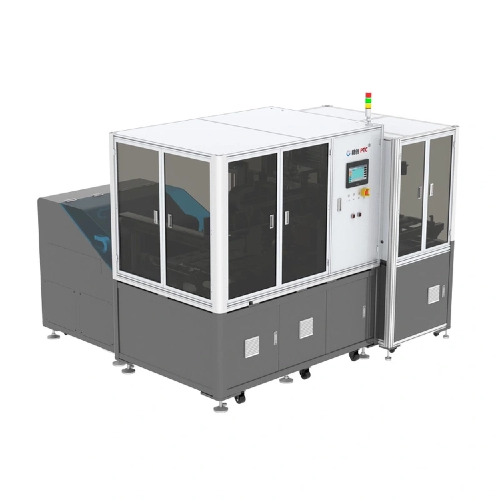

As technology advances, SAT continues to improve in accuracy, speed, and integration with automation systems, making it a crucial part of the future of manufacturing. At Suzhou PTC Optical Instrument Co., Ltd., we specialize in providing advanced SAT solutions that support manufacturers in achieving these goals. Our cutting-edge technology ensures reliable, real-time defect detection, enhancing both the efficiency and quality of your production process. For more information or to explore how our SAT solutions can optimize your operations, feel free to reach out to us. We are here to help elevate your manufacturing capabilities.

What materials can be tested with scanning acoustic tomography?

SAT can be used to test a wide range of materials, including metals, ceramics, composites, plastics, and more.

How does scanning acoustic tomography compare to other NDT methods like X-ray?

SAT is more sensitive, providing higher precision for detecting small defects and providing faster, real-time results compared to other methods.

What are the main advantages of SAT over traditional inspection methods?

SAT is non-destructive, offers high sensitivity, and is faster than many traditional NDT methods, providing detailed internal images in real-time.

Can scanning acoustic tomography detect surface defects?

SAT is designed to detect internal defects such as delaminations, voids, and cracks . But it is not capable for surface-defect inspections.

Is scanning acoustic tomography suitable for various industries?

Yes, SAT is versatile and can be applied in a variety of industries, including aerospace, automotive, semiconductor, and electronics, to ensure product quality and reliability.